Features

- Ideal for high-temperature, high-volume environments

- Temperature range of 32˚ – 200˚F (0˚- 93˚C)

- Flow rate range of 200 – 1000 lb/min (91 – 453 kg/min)*

- Media flow control for wheels up to 25 Hp (19 kw)

- Regulates flow of steel media and grit

- Normally closed

- No moving parts for low-maintenance operation

- 24 Vdc Power

- CE compliant

* Flow rate depends on media type

The VLP-24HT MagnaValve® is a normally closed magnetic valve that regulates the flow of steel shot and grit in wheel blast machines. The VLP-24HT is a low-maintenance valve — it has no moving parts so there are no parts to wear or break and it is completely sealed to prevent media dust from entering the valve. The VLP-24HT has rare earth permanent magnets for normally closed operation and an electromagnet for controlling shot flow rates. With power applied, the magnetic field is neutralized and shot is allowed to flow through the valve. When no power is applied to the MagnaValve, the permanent magnets stop all flow. If the power is interrupted for any reason, the permanent magnets securely hold the shot, thereby virtually eliminating shot leakage. The VD13HT valve driver on the VLP-24HT operates in temperatures up to 200˚ F (93˚C), making it the ideal MagnaValve for high-temperature, high-volume environments such as foundries and other similar blast cleaning operations.

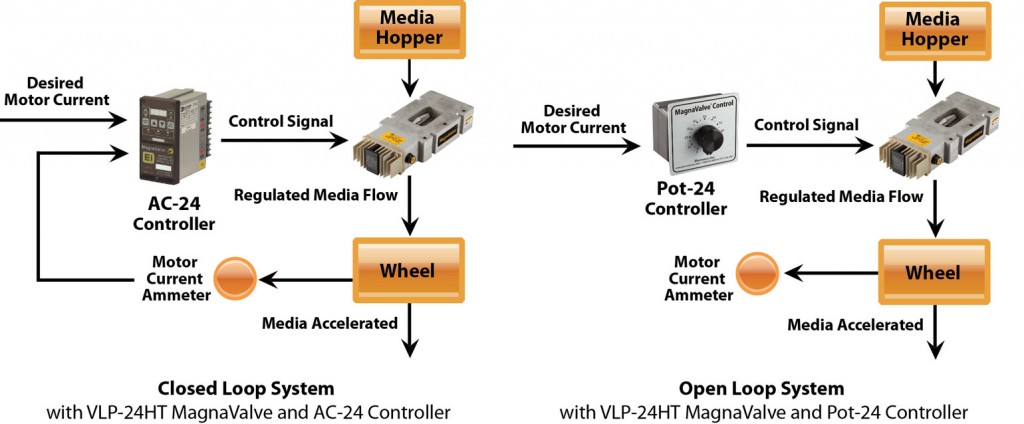

For an “automatic” closed-loop operation, an Electronics Inc. (EI) AC-24 Controller (sold separately) will detect the current load on the wheel motor and regulate the flow of media to the VLP-24HT. This closed-loop system will provide accurate and repeatable flow rates over a 200 – 1000 lb/min (91 – 453 kg/min) range. The EI POT-24 Controller (sold separately) provides “manual” open loop control.