Features

- Flow rate up to 3,000 lbs/min (1,361 kg/min) for for steel media*

- Variable flow rates

- Steel media flow control for wheels up to 125 Hp

- Provides motor amperage control when used with EI AC-24 Controller (sold separately)

- Remote VD-17 Valve Driver (included) has DIN rail or panel mount

- Normally closed

- No moving parts for low-maintenance operation

- 24 Vdc

* Flow rate based on S230 cast steel shot

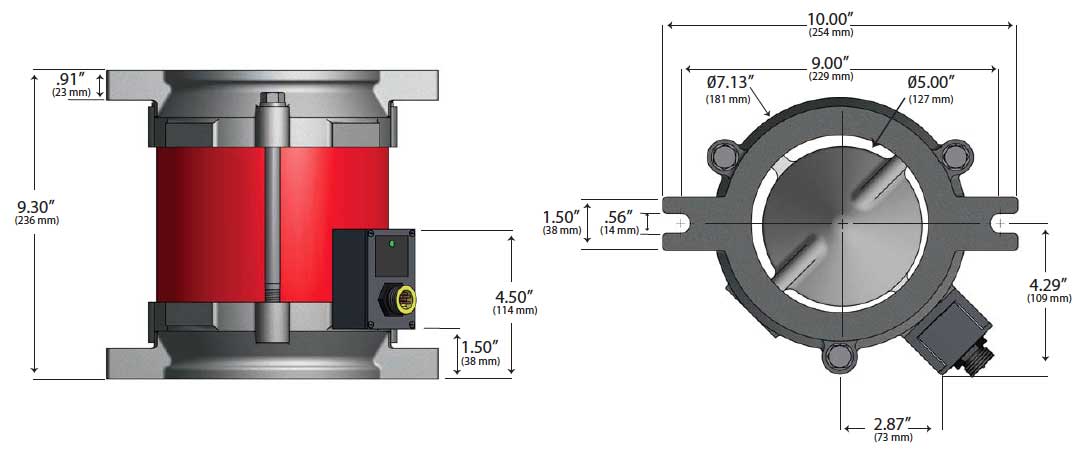

The WM 3000-24 MagnaValve® is a normally closed magnetic valve that regulates the flow of steel shot and grit in wheel blast machines. The MagnaValve’s construction includes a rare earth permanent magnet for normally closed operation and an electromagnet for controlling shot flow rates. With power applied, the magnetic field is neutralized and shot is allowed to flow through the valve. When no power is applied to the MagnaValve, the permanent magnet stops all flow. If the power is interrupted for any reason, the permanent magnet in the valve securely holds the shot. The MagnaValve reduces media usage, energy costs, machine downtime, and wear and tear on equipment.

The WM 3000-24 works with its companion controller, the AC-24 Controller, and customer-supplied motor current transformer (0 -5 Amps signal) to regulate wheel motor amperage to any value from no-load to full-motor load (the Remote Valve Driver comes with a 6 ft. 6-pin plug/cable for easy connection to a AC-24 Controller). This closed-loop system provides accurate and repeatable flow rates of up to 3,000 lb/min (1,361 kg/min). The EI POT-24 Controller provides “manual” open-loop control.

(US Patent 5,362,027)