Features

- Flow rate range of 120 – 1,200 lb/min (54.4 – 544 kg/min) 1

- ±5% full-scale accuracy 2

- Flow control for wheels up to 25 Hp

- Built-in flow rate sensor

- Variable flow rates

- Normally closed

- No moving parts for low-maintenance operation

- Includes 6’ plug and cable

- 24 Vdc

- CE compliant

1) Flow rate based on S230 cast steel shot

2) ±3 full-scale accuracy available with the 500-24B MagnaValve

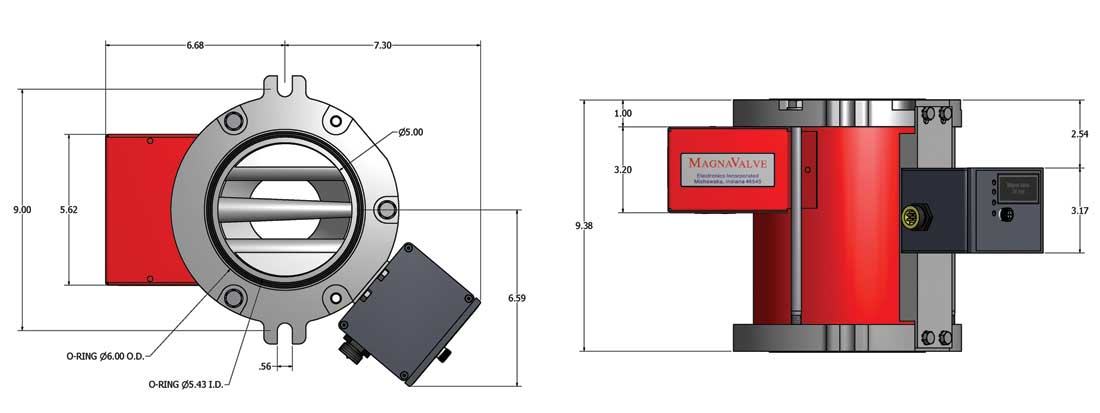

The MagnaValve® is a normally closed magnetic valve that regulates the flow of steel shot and grit in wheel blast machines. The MagnaValve’s construction includes a strong and stable rare earth permanent magnet for normally closed operation and an electromagnet for controlling shot flow rates. With power applied to the MagnaValve, the magnetic field is neutralized and shot is allowed to flow through the valve. When no power is applied to the MagnaValve, the permanent magnet stops all flow. If the power is interrupted for any reason, the permanent magnet in the valve securely holds the shot.

The MagnaValve’s built-in sensor measures flow rate and when coupled with the EI FC-24 Controller (sold separately), it provides accurate and repeatable flow rates in a closed-loop system, meeting the requirements of AMS 2430, AMS 2432 and other aerospace standards.