Features

- For non-ferrous media

- Requires little maintenance due to no moving parts

- Operates from 24 Vdc

- Relay contact output

- Push-button setup

- LED indicators

- CE compliant

The MFD-P1 Sensor is a media flow detector for pressure-type abrasive blasting machines. The MFD-P1 Sensor uses a charge-coupled amplifier that is connected to a sensing ring placed in the flow path of the abrasive blasting media. Each particle passing the ring shares a minute charge with the ring, converting it to a voltage used to activate the output relay contact.

Setup is simple. The zero and span functions are automatic—pushing the “zero” button acquires zero for the no-flow condition and pushing the “flow” button sets the sensor gain and activates the relay. The relay contact will transfer whenever the flow is 50-100% of the programmed setting.

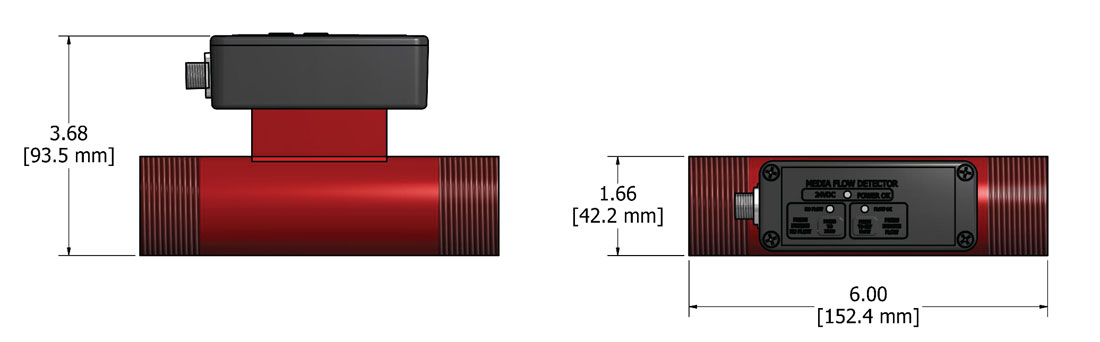

The MFD-P1 is enclosed in a 3.6″ x 1.5″ x 1.5″ aluminum housing and is attached to a sensing ring in its mounting base. The mounting base is available in various sizes to fit most abrasive blast machine configurations. The 6-pin plug allows for easy connection of the sensor to the power supply and machine controls. The sensor is placed in the blast hose near the mixing chamber. LEDs on the top of sensor indicate green for “Flow OK” or red for “No Flow”. The internal relay is activated during green “Flow OK”.

Cable Ordering Information

Cable is ordered separately. Three lengths are available:

| LENGTH | CPN |

| 6′ / 1.8 m | 940010 |

| 12′ / 3.5 m | 940011 |

| 15′ / 4.5 m | 940012 |