by Kathy Levy

Electronics Inc. has the answer

Electronics Inc. has the answer

The On | Off Hopper Fill MagnaValve® eliminates media leakage and the maintenance problems associated with air cylinders and mechanical valves. Other benefits include:

- No moving parts for low-maintenance operation

- Securely holds the media – even in a power failure

- Completely sealed against debris

- Easily retrofitted to older machines

- Provides a dependable and steady media flow

- Works with most ferrous media including cut wire, cast steel shot and grit, and stainless steel cut wire

How a MagnaValve works

The MagnaValve has rare earth permanent magnets for normally closed operation and an electromagnet for controlling media flow rates. When power is withheld from the MagnaValve, the permanent magnets stop all flow. With power applied, the magnetic field is neutralized and media is allowed to flow through the valve.

If the power is interrupted for any reason, the permanent magnets securely hold the media, thereby virtually eliminating media leakage.

Why the media mix is important

Media should be replenished at the same rate the spent media is discharged through the dust collector. This will maintain the most consistent process for either peening or abrasive blast cleaning. Additions of large amounts of media over long periods will upset the balance of media in the machine and consistency will be sacrificed. For instance, the addition of several hundred pounds of new media in an abrasive blast cleaning machine will make a significant change in the working mix. Product that is blast cleaned after the addition of media will be treated differently and it may not be acceptable.

An On | Off Media Fill MagnaValve provides a dependable flow of media whenever you need it, thereby maintaining a consistent media mix.

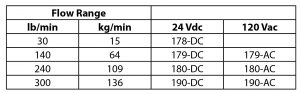

Choose the On | Off Hopper Fill Media MagnaValve that best meets your needs

For more information, visit www.electronics-inc.com/product-category/on-off-hopper-fill-magnavalves or call the EI sales support team at 1-800-832-5653 or (574) 256-5001.

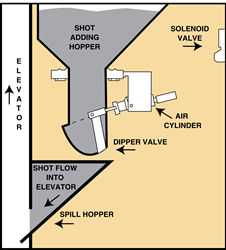

The On | Off Hopper Fill MagnaValve® replaces Solenoid Valves, Air Cylinders and mechanical Dipper Valves which are difficult to regulate and are prone to breakdowns.