The following article is from the 2022 Winter Shot Peener magazine.

by Erik Waelchli | President of IBD Connection, Inc. and Electronics Inc. Consultant

INTRODUCTION

Can or should Almen strips be archived? Does the arc height after peening change over time and if yes, by how much? If there is a change, is the change of relevant magnitude?

These questions came up during a weekly engineering meeting at Electronics Inc. (EI). No one had a definitive answer so we initiated a long-term study. The test was started in March, 2019 and was concluded with the last measurement taken on September 23, 2021.

PROCEDURE

1. Samples

a. Two A-strip sample sets of twenty (20) pieces each were defined:

i. EI – A-1 Strip Quality: Lot 026814-26

ii. EI – A-2 Strip Quality: Lot 034438-86

2. Saturation curves and machine setting

a. Two saturation curves with 1, 2, 4 and 8 revolutions, were created before the twenty samples were peened – an intensity of 12-A was the target:

i. A-1 – #1 sat.-curve I = 11.4 / T1 = 2.8349

ii. A-1 – #2 sat.-curve I = 11.6 / T1 = 3.0499

iii. A-2 – #1 sat.-curve I = 11.2 / T1 = 2.6465

iv. A-2 – #2 sat.-curve I = 11.2 / T1 = 3.6838

b. The intensities were confirmed as stable and the machine settings were chosen at:

i. Shot type: CCW 28

ii. Flow rate: 10 lb/min

iii. Table speed 2 rpm ( 29″ pitch diameter)

iv. Nozzle diameter 0.3125″

v. Nozzle stand-off distance 6″

vi. Nozzle angle 90˚

3. Samples Test Run

a. Two test runs were made as a maximum of 24 strips fit in the turntable of the custom air-blast cabinet in EI’s test lab. The first test run had samples 1 through 10 of the A1 and A2 quality, and the second test-run had the samples 11 through 20 of both strip qualities. This way we assured a proper mixing of the samples in both lots.

b. For an unknown reason, A-2 strips #2 and #10 resulted a significant higher arc-heights (>0.0150″) and were

therefore ignored.

4. The arc-height measurement cycles

a. Immediate: Samples 1A were measured on 2019-03-25 at 11:50 pm, the A2 samples at 1:45 pm the same day.

b. 3 – 5 hours later: Samples A1 first, then A2 at 4:45 the same day

c. 24 hours later: Samples A1 & A2 starting measuring at 2019-03-26 – 11:50 pm

d. 4 days later: Samples A1 & A2 on 2019-03-29 – 10:00 am

e. 8 days later: Samples A1 & A2 on 2019-04-02 – 11:00 am

f. 17 days later: Samples A1 & A2 on 2019-04-11 – 10:45 am

g. 35 days later: Samples A1 & A2 on 2019-04-29 -11:40 am

h. 63 days later: Samples A1 & A2 on 2019-05-27 – 4:30 pm

i. 120 days later: Missed this reading

j. 182 days later: Samples A1 & A2 on 2019-09-23 – 15:30 pm

k. 241 days later: Samples A1 & A2 on 2019-11-21 – 2:30 pm

l. 301 days later: Samples A1 & A2 on 2020-01-20 – 3:30 pm

m. 371 days later: Samples A1 & A2 on 2020-03-30 – 2:30 pm

n. 545 days later: Missed this reading

o. 731 days later: Samples A1 & A2 on 2021-03-25 – 2:30 pm

p. 913 days later: Samples A1 & A2 on 2020-09-23 – 12:00 pm – Final

RESULTS

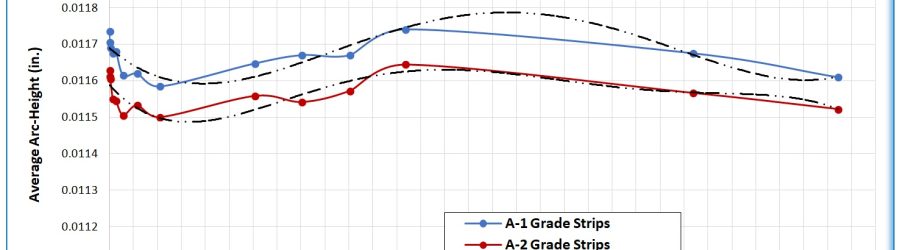

The results are best depicted in graphical form. The graph on page 22 shows the averages of the twenty (20) strips at each test date and a 4th order polynomial trend line for each test set. While this graph is rather dramatic, the actual numbers and decay percentage are less so.

DISCUSSION & CONCLUSION

Interesting to note: The arc-height values have decayed rather quickly by up to ~ 1% in 60 days, but then they creeped up to near the original value again in 365 days—one year! Then after 913 days, the decay resettles at around 1%. At this point the test was concluded. The measurements were conducted by two individuals with two different gauges. It could now be argued: Is this 1% error over time significant? It is the author’s opinion that there are many other variables affecting the peening result, maybe by much more than this small error.

So, with this reporting update the conclusive statement stays the same:

Almen strips can be archived as the results are only affected by a minimal amount over time.