Steel Shot Media Valve for Air Blast Machines

| Model | Flow Rate Range |

| 676-24 | .2 – 2 lb/min (.1 – 1 kg/min) |

| 677-24 | 1 – 10 lb/min (.45 – 4.5 kg/min) |

| 678-24 | 3 – 30 lb/min (1.4 – 13.5 kg/min) |

| 679-24 | 10 – 100 lb/min (4.5 – 45 kg/min) |

| 690-24 | 30 – 300 lb/min (13.6 – 136 kg/min) |

*Flow rates based on S230 cast steel shot. Flow rate chart on data sheet.

Features

- SteadyFlow Technology for smooth media flow

- 24 Vdc

- ±10% of point, 10% – 100% Setpoint

- Ethernet with Embedded Webpage

- Normally closed

- Built-In Servo

- No moving parts for low-maintenance operation

- Desired Flow Jump-To

- Meets SAE AMS 2432

- Customizable LCD screen

- Simplified installation and calibration

- Sealed enclosure

- CE compliant

- 0 – 10 Vdc, 4 – 20 mA, I/O

- Includes a six ft (1.83 m) plug and cable

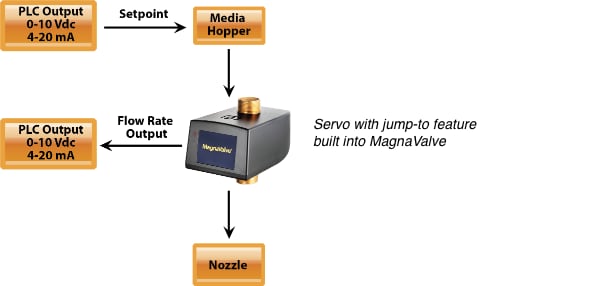

The MagnaValve® is a normally closed magnetic valve that regulates the flow of steel shot and cut wire media in air blast machines. The MagnaValve has a built-in sensor that measures flow rate and, along with a built-in servo and flow jump-to feature, provides accurate and repeatable flow rates. The flow jump-to feature starts media flow at the desired flow rate instead of ramping up to the desired rate. The MagnaValve can be factory calibrated for various media types and sizes. It will be calibrated for the media type, size and flow rate specified on the purchase order.

The MagnaValve has a strong and stable rare earth permanent magnet for normally closed operation and an electromagnet for controlling shot flow rates. When no power is applied to the MagnaValve, the permanent magnet stops all flow. With power applied, the magnetic field is neutralized and shot is allowed to flow through the valve. If the power is interrupted for any reason, the permanent magnet in the valve securely holds the shot.

The MagnaValve provides reliable, repetitive, and consistent media flow rates for shot peening and blast cleaning applications. The MagnaValve makes it easy to document flow rates and establish or repeat a good set-up. The valve meets the requirements of SAE AMS 2432 and other aerospace and commercial specifications.

Clear and comprehensive installation manuals simplify installation for the 600 Series MagnaValve. In addition, the products are supported by the Electronics Inc. application engineering staff.